Pinion Industrial

GEARBOX SOLUTIONS

FOR COMMERCIAL AND INDUSTRIAL USE

We deliver the heart of drive technology for commercial bicycle use.

From rental bike fleets to heavy-duty cargo e-bikes – for bicycles, tricycles, and quadracycles.

TECHNOLOGY

A SHIFT IN URBAN MOBILITY

Overcrowded city centres, poor air quality and increasing demands on urban logistics – inner-city transport must become more sustainable. Heavy-duty cargo bikes in particular have great potential and can successfully replace traditional delivery cars, trucks, and vans in many scenarios. But classic bicycle components do not stand a chance under such harsh conditions. Reliable vehicles require reliable shifting solutions! Pinion gearboxes are built to withstand the relentless stresses and strains of the most demanding commercial and industrial cargo bike applications.

GEAR SHIFTING

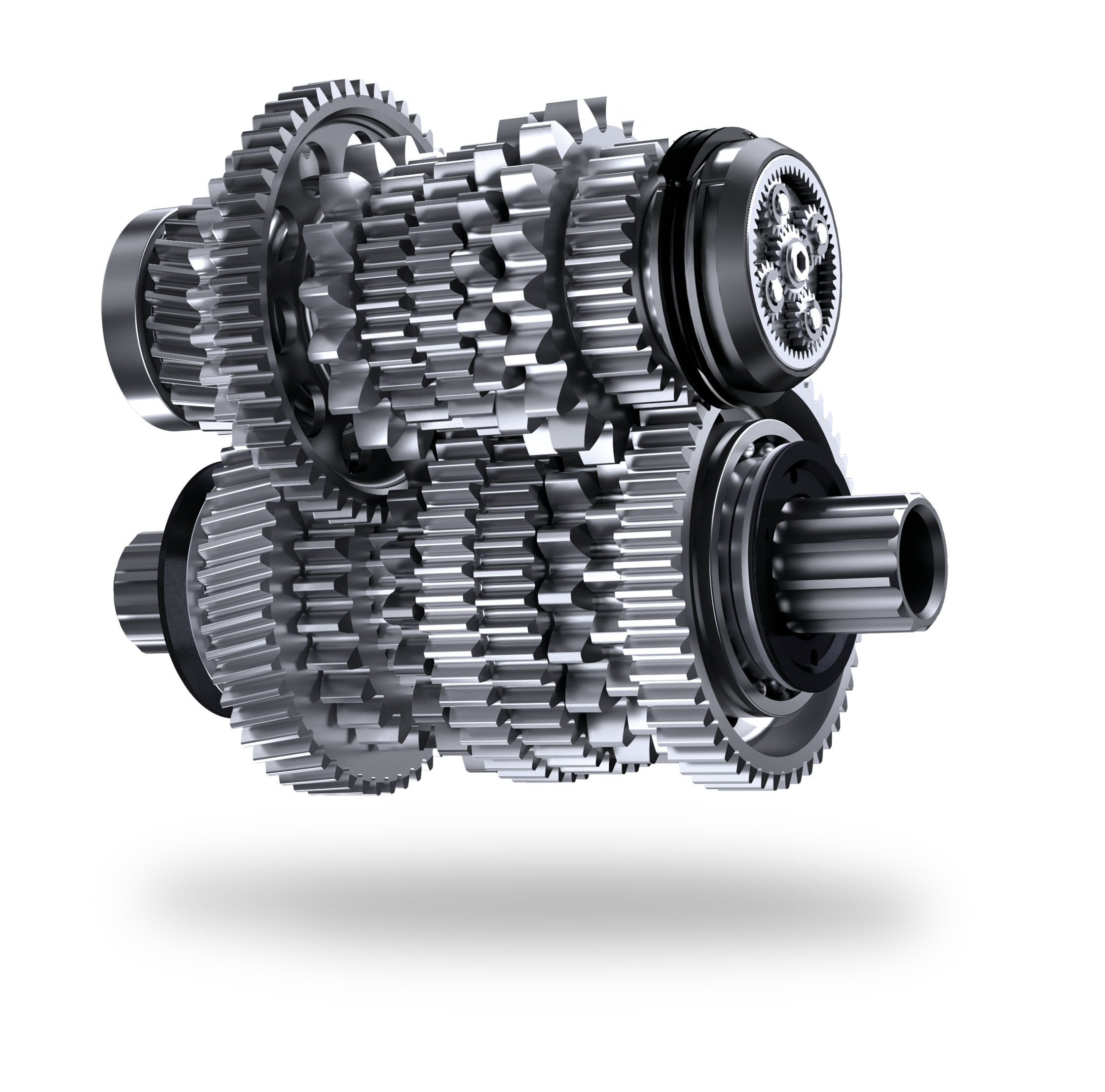

BASED ON PROVEN

AUTOMOTIVE TECHNOLOGY

Pinion offers robust drive technology in a series of gearboxes designed specifically for heavy-duty applications. The gearboxes use spur gearing based by sophisticated automotive transmission technology. The result is a shifting system that is virtually wear-free, requires no adjustment, and provides outstanding long-term reliability. With its fully sealed construction and flexible positioning within the drivetrain, Pinion gearboxes are a driving force in the cargo bike market.

TESTED IN-HOUSE,

PROVEN AROUND THE WORLD

At Pinion we develop and test all our products based on established automotive standards. From lifetime endurance tests to overload testing, from misuse testing to exposure to the most extreme conditions. We leave no data-sheet unturned to ensure that we deliver the most durable and reliable product.

For nearly 10 years, passionate cyclists around the world have relied on Pinion gearboxes for bicycle touring, mountain biking, urban riding and e-bike exploration. Adventure cyclists can spend years on their journeys and cover distances of 30,000-40,000 km at a time. Some Pinion gearboxes have logged in excess of 100,000 km. Whether low in the salt flats, high in the Himalayan mountains, or on a quick ride across town, Pinion gearboxes are virtually wear-free and shift precisely in even the toughest conditions.

PINION FOR BICYCLES, TRICYCLES

AND QUADRACYCLES

Electric cargo bikes have unique design requirements for specific applications. The Pinion system can be integrated into a variety of drivetrain configurations, whether it has two, three, or four wheels. The Pinion gearbox gives you the flexibility and freedom to design and build the bicycle, tricycle or quadracycle that is perfectly fits your cargo and your application.

HEAVY-DUTY QUADRACYCLE

CARGO TRICYCLE

CARGO TRICYCLE

HEAVY-DUTY CARGO BIKE

TCO

TOTAL COST OF OWNERSHIP

RELY ON PINON TO INCREASE YOUR UPTIME AND REDUCE YOUR COSTS

- Designed for long-term use

- Extended and predictable service intervals

- Lifetime extension of mobility warranty through Pinion Industrial Care

- Factory overhaul incl. 2 years follow-up warranty

What our customers say

STRONG. RELIABLE. CAREFREE.

THE CARGO GEARBOX

The embodiment of German engineering and high-end drive technology in a compact and sealed housing. The T-Line rely on the Pinion drive technology which is based on sophisticated automotive drive technology. Extremely robust, 100% reliable, virtually maintenance-free, efficient and cost-effective. All this combined with service concepts that suit commercial and industrial applications.

PINION EXCLUSIVE:

NEUTRAL GEAR OPTION

FOR SAFE MANOEUVRING

Pinion T-line gearboxes are the only shifting systems on the market with an optional neutral gear. This allows reverse movement of the bicycle without the crank arms rotating backwards. While operating a heavy vehicle, this feature significantly improves ergonomics and reduces the risk of injury as compared to conventional cargo bikes.

T-LINE SPECIFICATIONS

Pinion T-Line gearboxes can be integrated into various drivetrain configurations. Gearboxes are available in 6-, 9- and 12-speed versions with gear ratio ranges increasing with the number of gears. The 6- and 9-speed versions are also available with the unique neutral gear option.

Frame connection

Sprocket – Spider mount

NEW Chain line

Maximum input torque

Pinion Standard

Pinion Center Lock

50 mm

250 Nm

Axle standard

NEW Q-Factor

Oil-Fill

Service interval

Pinion Standard

166 mm

60 ml Pinion gearboxoil

once a year

|

|

|

||

| Number of gears | 12 | 9 | 6 | |

| Overall ratio | 600% | 568% | 295% | |

| Gear steps | 17,7% | 24,3% | 24,3% | |

| Gain ratio in first gear | 1,82 | 1,82 | 0,95 | |

| Gain ratio in fastest gear | 0,30 | 0,32 | 0,32 | |

| Gearbox Weight | ca.2100g | ca. 2000g | ca. 1800g | |

| Neutral gear option | - | ✓ | ✓ |

PERFECTLY

MATCHED ACCESSORIES

T-line accessories let you adapt the gearbox for your specific drivetrain requirements. The gearboxes can be configured for use in chain-drive (1 1/8” single-speed or industrial type “08B-1”) or belt-drive configurations. Other accessories include various crank-arm lengths, covers, chain- and belt-tensioners, workshop equipment and tools.

YOU ARE INTERESTED IN

OUR GEARBOX SOLUTIONS?

We will answer your request personally and work out the perfect solution together with you.

CEES VAN VLIET

Sales Manager

Stefan Oelker

Sales Manager